Manufacturing / Logistics

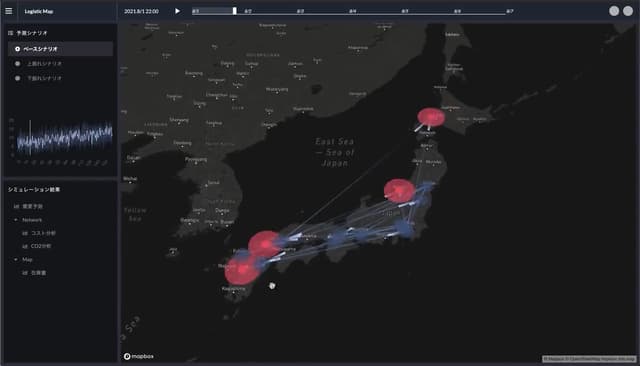

The supply chain is an important part of our lives and economy. From the purchase of raw materials to the production of products and the delivery of goods to our hands, skilled technicians at each location operate planning operations that require an enormous amount of effort, taking into account a variety of factors that fluctuate on a daily basis. GRID optimizes all operations related to the supply chain with AI to support our daily lives.

課題

Responding to Unexpected Risks

Reproduction of field operations on a digital twin. A precisely reproduced digital twin allows you to test your actions in any situation.

2024 Problem

AI derives optimal operations according to set KPIs on the simulator.

Lack of Coordination

AI pseudo-generates multiple demand forecast scenarios to prepare for an uncertain future. Optimal plans corresponding to each scenario are calculated, and the results are analyzed to enable robust planning.

ReNom APPS

Procurement Plan

Improving operational efficiency while meeting deadlines. AI optimizes the procurement of materials, parts, and raw materials necessary for production: when, which materials, in what quantities, from which suppliers, and to which locations.

Compounding Plan

Quality Improvement through formulation optimization. AI will derive the optimal blending plan for raw materials, taking into account daily fluctuating factors such as raw material inventory, product inventory, and product demand, and how much of the raw materials should be used and how they should be combined.

Production Schedule

Maximize profits and streamline operations. Among production plans, we optimize production plans for "when, how, which lines, and how many to produce," especially for small schedule planning operations that are subject to daily plan revisions due to unexpected fluctuations.

Loading Plan

Improving transportation efficiency while realizing stable supply. We optimize loading and unloading plans, taking into consideration the order and rules of loading and unloading according to the logistics schedule, and which products are to be loaded in which order.